Richard Schneider has dedicated over 36 years to the pursuit of Quality Assurance. His experiences include multiple long-term roles as a Multi-Plant Quality Director, a Supplier Development Leader for a large OEM in Asia, and extensive supplier development travels in mainland China. He mentors quality professionals and is a student of the Chinese Mandarin language.

Creating a thorough quality plan when a new project comes in is a critical part of the manufacturing and quality control process. Since quality planning is intended to circumvent product failures, and the burden of success lies with the quality team, there’s pressure to prioritize and execute the quality planning effort thoroughly, while maintaining (often firefighting) sustaining programs that produce too many defects.

However, the quality professional is often over-taxed to the limit, so this requires the determination and stamina that those looking for the easy path won’t sign up for. The adage of the candle that burns at both ends fits well. As a result of this pressure and lack of time or resources, it’s easy for quality professionals to rationalize taking shortcuts during quality planning.

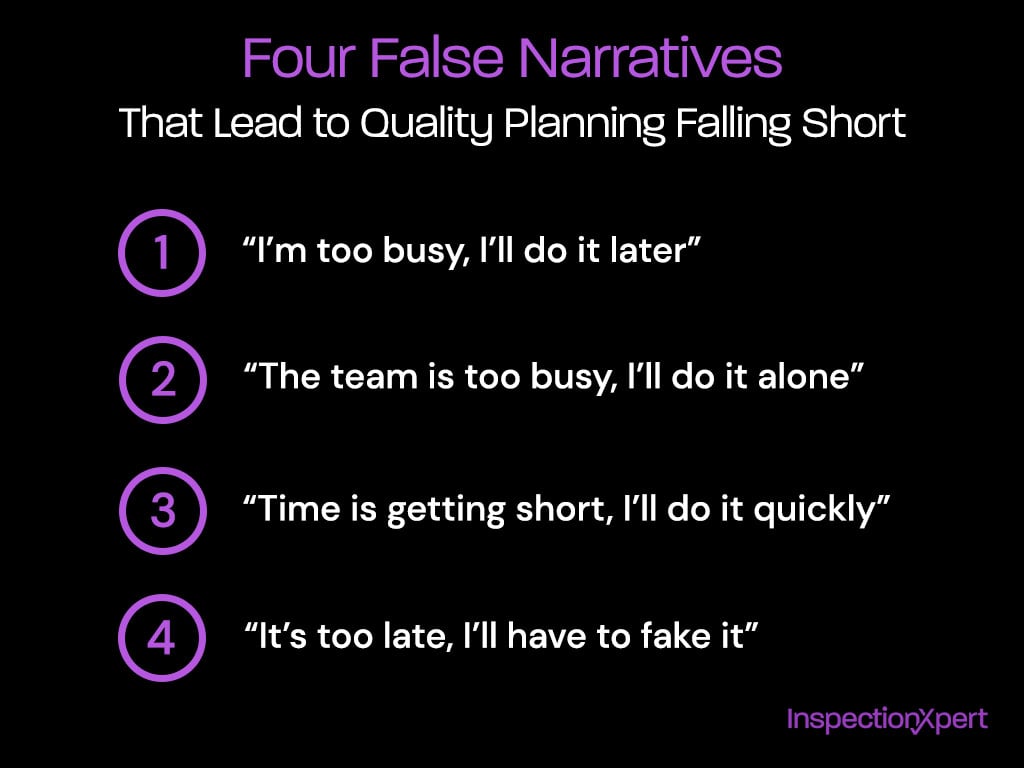

The following are four common false narratives that result in quality planning falling short, and how you can overcome them.

There’s no time like tomorrow to do what needed to be done yesterday. This is the axiom of the overworked, under-staffed, stressed out quality professional when suffering under the sins of their predecessors. Drawing reviews, supplier audits and selection, FMEAs, inspection plans, and advanced programming of inspection equipment from CAD are some of the steps that must be completed before raw material arrives at the dock. But when it becomes apparent these things won’t get done because management cannot see the urgency, or will not assign the resources needed, a cloud of impending doom starts to overshadow all other efforts.

The frustration is often justified when the system is broken and the way out is not always clear, but there is a way out.

TIP #1: Prioritize quality planning tasks by dividing the day, doing it in writing, and don’t deviate.

Quality planning requires a cross-functional team. Sales, Engineering, Purchasing, Production, Quality Engineering, and Inspection all need to be part of the effort, but how often does the full team make themselves available? Everyone has too many meetings, long backlogs, unanticipated demands, and PTO. After too many canceled meetings, the quality professional often succumbs to the temptation to be their own team and do the work themselves. Sometimes they produce a draft of the required documents and email it out for a response, and then walk the office area trying to corner each member of the cross functional team one by one to present the plan, solicit input, and get a signature.

This is a desperate attempt to satisfy the team approach, and while it’s proof of your commitment, in this scenario there is no group dialogue. There is no cross-pollination of the ideas needed to develop a creative and effective quality plan. Only a cross-functional team can do that.

While this approach seems to be better than nothing, it's not better by much, and it will set you up for a far bigger, far worse, and potentially career ending disaster. Don’t fall into this trap.

TIP #2: Invite the site leader to every quality planning meeting as informational only. Tell them this in a separate email, explaining that attendance has been low and requesting their follow-up with no-shows.

As the deadline looms large and progress is slow or nonexistent, corners are cut, assumptions are made, and requirements are overlooked. The hastily built quality plan, once envisioned as the brick house in the story of The Three Little Pigs, now appears more like a house of straw. It has four walls, a roof, windows and a door, but it cannot stand up to the challenges it will face with so many variables. A hastily built quality plan is like trying to have a baby in four months because you brought two midwives to the pregnancy. It’s simply not possible.

True quality planning takes time. When the wrong material is delivered, poor tooling is designed, the machine set-up is incorrect, or an inadequate inspection plan is created, it can’t prevent the defects like it should and it can’t detect the defects that result. Now you’ve masked the project in a façade of quality assurance. The false narrative might assuage your conscience, but it won’t for long. When the curse of bad quality strikes, you realize that another low quality product has been added to the legacy of similar predecessors, making the next new project that much harder to prepare for.

TIP #3: Tour the Nonconforming Material cage every time the temptation to rush a quality plan spikes. This reality check will remind you of the value of your personal investment in integrity.

An email appears in your inbox requesting the quality plan submission. Maybe it's due tomorrow, or on Friday, or maybe even next week, but you realize that it’s now an impossible task to complete in any fashion that even resembles a quality plan. No drawing review was done, no supplier qualification or formal flow down was performed by Purchasing. Engineering designed the tooling without regard for Poka-Yoke, no advanced programming of lab equipment was done from CAD, and parts are already being submitted to the lab for inspection.

You realize nobody is going to accept any excuses, however true or justified you think they may be. So you open up the Excel templates and you start to populate fields based on past experience. The resulting generic FMEA has a lot of perfectly plausible sounding information that may pass customer review. You might even rationalize it in your mind because it is based on your past real-world experience. But once you get to the gage R&R and the SPC data, you only have two choices: leave it blank and deal with the flak you will receive, or fake it, which is far worse because it involves falsifying data.

TIP #4: If things reach this point after taking to heart the three previous tips, then you will be better off taking the initial heat for missing the deadline. This will get management’s attention, and if it truly is a cultural problem and not your own procrastination, that will surface in a big way. And if it costs you your job, there’s no better way to explain to your future employer why you are looking for work.

Although it can be understandably easy to fall into these false narratives, the truth is that you never really know what the result of a hastily created quality plan will be. When the quality planning effort does fail, and sometimes in a very big way, it can far exceed your darkest fears. Any failure could be catastrophic, and if you keep that in mind, you will be safer in the long run.

Think about the foolish pig in the story who built his house with straw. That is a quality plan created by cutting corners. At first the walls will only shake, but then the roof will shudder, and soon after the house will fall. Instead, prioritize creating a strong, thorough quality plan with input across teams. In the long run, you will avoid failures and improve quality across the board.

Read more about the importance of quality planning and advice for QA professionals.

About the Author:

Richard Schneider is the CEO of All Things Quality Inc. where he partners with job shops to help them create predictable, reliable and efficient ways to document customer and regulatory requirements, so that manufacturers can become the preferred supplier among their customers.

Richard holds a degree in Business Administration, has multiple ASQ certifications, and is an advanced level Zeiss Calypso CMM Programmer. If you would like to reach him for comment or consultation, he can be reached at rjohnschneider@hotmail.com, or (612) 414-4629.

Copyright 2026 Ideagen, All Rights Reserved